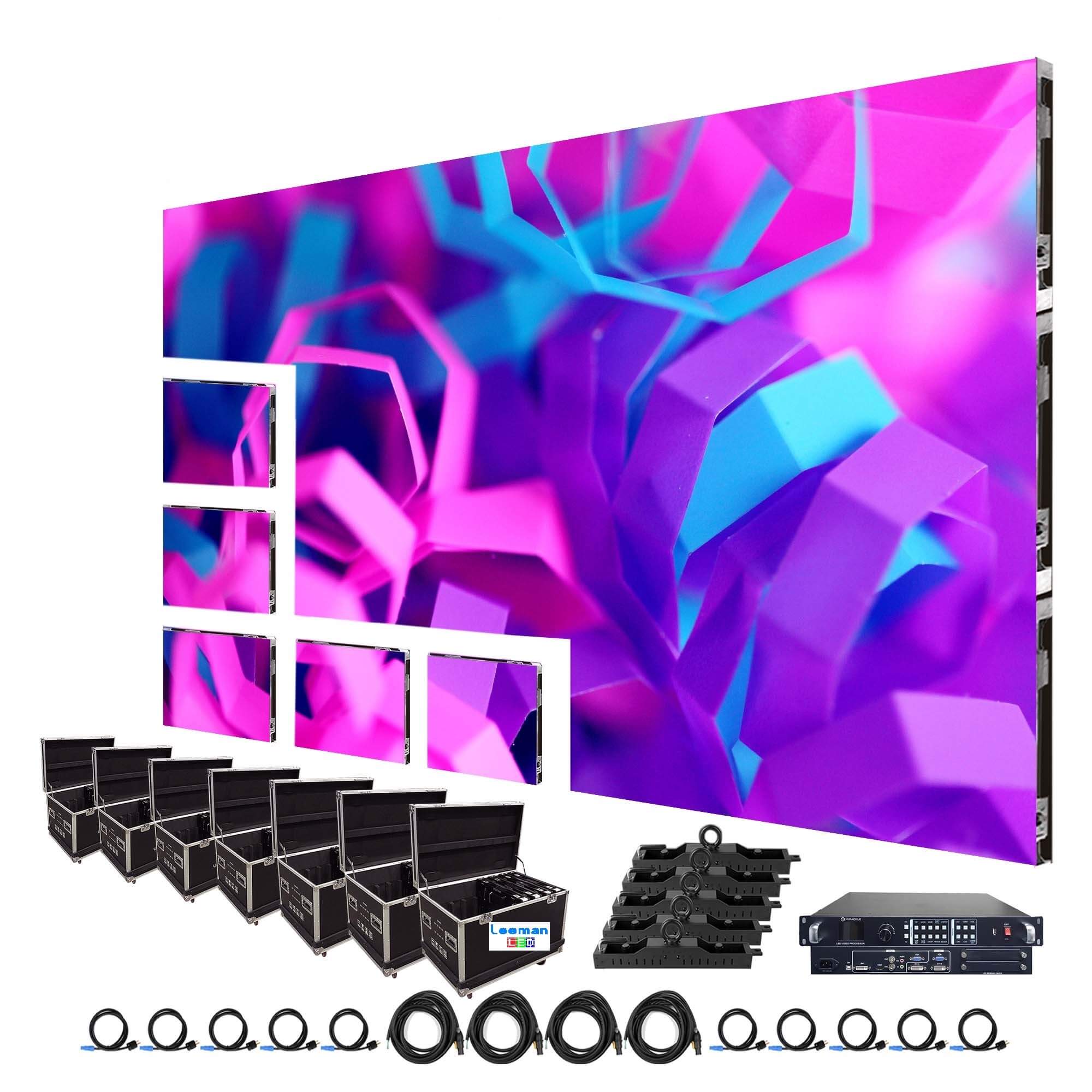

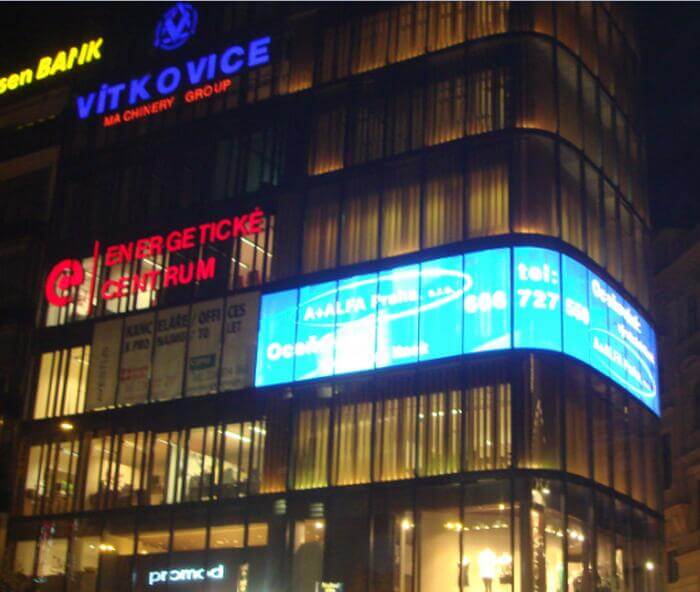

Pixel pitch of LED displays is a crucial factor you should consider. For outdoors, you may need a LED display with high brightness but less requirement for pixel pitches. Normally, outdoor LED displays exceed P2.0 and higher in pixel pitch. But if you need high definition for stage or indoor display, small pixel pitch LED display is necessary. In recent years, as LED technology evolves, small pixel pitch LEDs has expanded LED display application for indoor usages. As demand for smaller and smaller pixel pitch LED displays raised, Mini LED and Micro LED displays emerged, hence the MiP technology was born and MiP LED displays become more and more popular.

What is MiP LED Display?

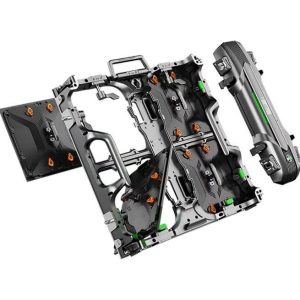

MiP stands for Micro LED in Package, which is a new LED packaging technology based on Micro LED. MiP technology dices Mini/Micro LED panels into small pieces and packages each piece independently. It increases yield and prominently lowers cost for LED display manufacturing.

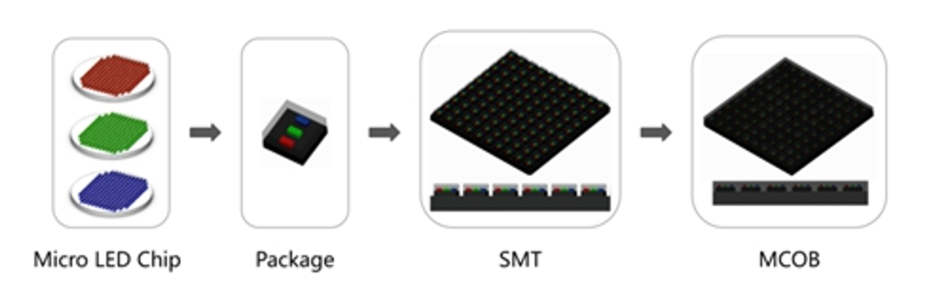

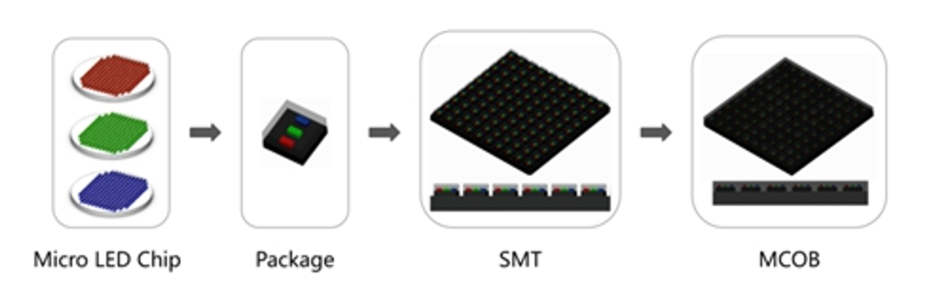

MiP Technology Procedures

MiP technology follows a common procedure for LED packaging as below picture shows.

Common Methods of MiP technology

There are two common methods for MiP LED packaging, one is the integrated pixel packaging and the other is the independent pixel packaging.

Comparisons with SMD, COB, IMD LED technologies

SMD technology is the most mature LED package technology but has drawbacks in reliability. Damaged LED diodes or failures can happen during production process. Another shortcoming of SMD technology is due to its physical size, which means it’s difficult to reach a pixel pitch below P1.0.

COB technology can reach small pitches even like mini-LED and micro-LED; the shortcoming for COB lamps can be its maintenance. It’s difficult to repair a single lamp on a COB module. When welding, a ring can be left on the surrounding lamps.

IMD technology is a combination of SMD and COB. IMD covers small pixel pitches between 0.4 – 0.9mm and has better anti-bumping feature than SMD technology. One IMD can be used for only pixel pitch.